Unlocking the Potential of NZ Timber Design Costs

-

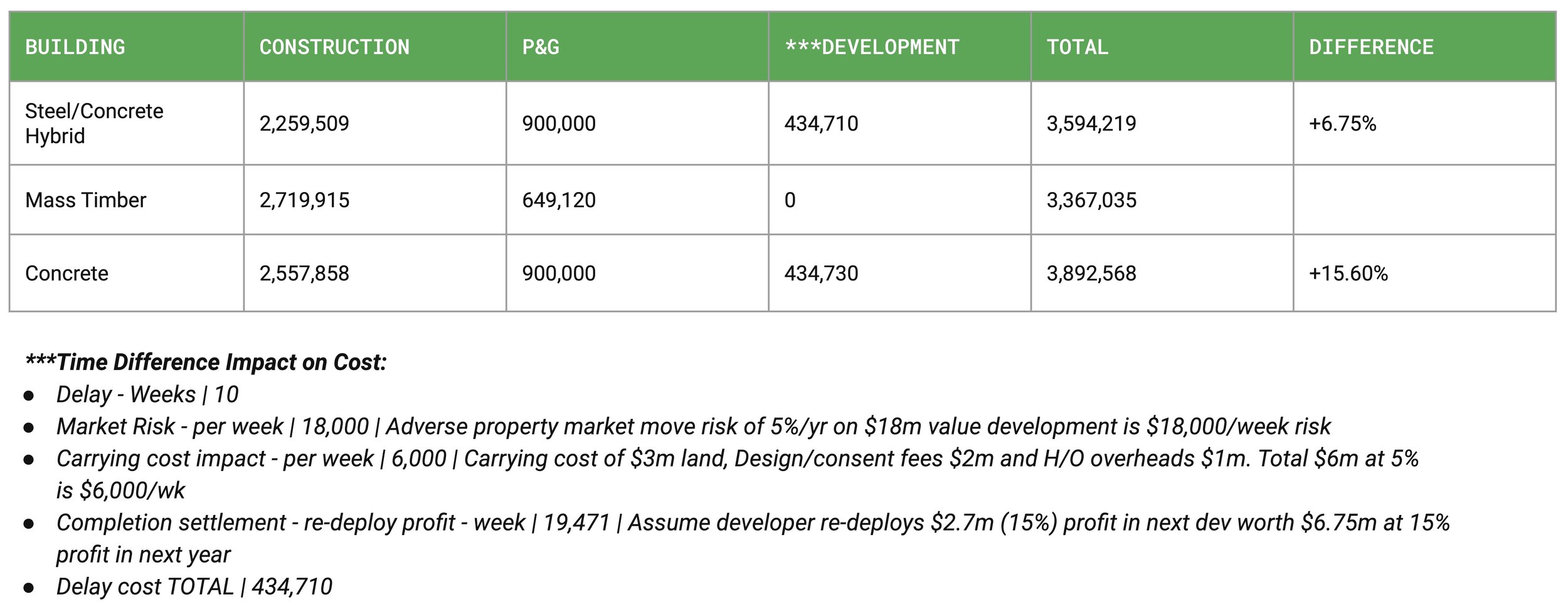

Cost needs to be viewed holistically, factoring in materials and construction cost, the impact of construction time to the developer, as well as the value of the building. Mass timber typically has a lower overall cost, and higher building value. To realise these benefits though, it is important to engage mass timber suppliers early in the Concept Design stage to optimise the spans and the grid pattern.

-

Typically mass timber material costs have been slightly higher than traditional, although time savings outweigh this. However in recent times steel prices have increased over 40 percent, and availability and lead times for steel and concrete have pushed out to as much six months.

In the meantime, the opening of the local CLT factory at Red Stag has brought competition and reduced costs of CLT in New Zealand. It has also provided significant capacity to the market, without the risk of international shipping.

-

Mass timber projects are on average 30 percent faster to build. Speed with mass timber is due to the prefabrication of large components that are ready to screw into place. Waiting 3 weeks for concrete floors to set can be eliminated with CLT flooring, which can be up to 16.5m x 4.5m in panel size (Red Stag only).

Construction time impacts costs in several ways:

P&G - site overheads are carried over a shorter time period. Big ticket items like scaffolding, crane time and lifts, and labour are minimalised.

Developers also need to factor in the impacts of longer construction programmes on:

Adverse market movement risk – on property values and cost escalation.

The longer carrying cost of land, design/consent fees, and overheads.

Early sale or tenanting, and the time value of money from that, calculated either as an interest saving or as the early re-deployment of profits to the next development.

-

Consumers and businesses are increasingly demanding sustainability in the buildings they buy or lease. The focus has turned to the ‘embodied carbon’ of the materials used because this has a big impact on climate change. This will soon be regulated in New Zealand through the Building for Climate Change programme. Businesses are starting to demonstrate their sustainability credentials through their buildings.

As a result there is a growing evidence base demonstrating premiums for mass timber buildings. For example, Lend Lease in Australia have reported that their mass timber office buildings in Barangaroo Sydney and Brisbane have attracted an estimated $50-75/m2 and $25/m2 lease premium respectively. This represents a 4-8% premium compared to traditional materials.

SOURCE: CASE STUDY VIA LOGIC GROUP

Mass Timber vs Concrete/Steel | Cost Comparison

Construction = Structure/Foundation cost, including all material Specific costs like fire, weather and acoustic

Mass Timber vs Concrete/Steel | CO2 Emissions

Structural Comparison Only